- Home

- Our Services

- Teflon / PTFE Coating

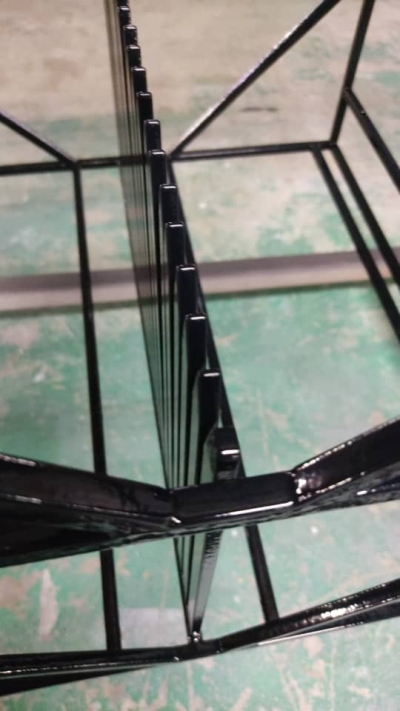

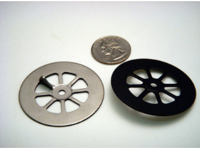

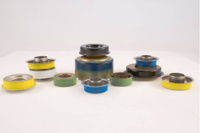

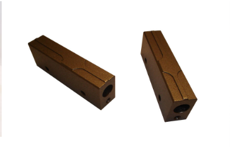

Teflon non-stick industrial coatings are available in both liquid and powder. The versatility of Teflon coatings allow almost unlimited application to a wide variety of parts sizes and configurations, always adding value far beyond the inherent non-stick qualities. Versatility unmatched by any other engineered material. Industrial Teflon coatings spray on like paint and bake to a tough, inert finish.

By combining heat resistance with almost total chemical inertness, excellent dielectric stability and a low coefficient of friction, non-stick industrial coatings offer a balance of properties unbeatable by any other material. With an industrial Teflon coating, the coefficient of friction is generally lowered to a range of 0.02 to 0.15, depending on the load, sliding speed, and type of coating used. Dry lubricant coatings are special versions of Chemours technology designed to provide lubrication under high-pressure/velocity (PV) conditions.

These products are solvent-based, one-coat systems that are usually cured between 148°C/300°F and 371°C/700°F. Teflon coating services can be applied to carbon steel, aluminium, stainless steel, steel alloys, brass and magnesium as well as non-metallics such as glass, fiberglass, some rubber and plastics. Optimum adhesion is obtained by roughening the surface before applying the industrial coating.

By combining heat resistance with almost total chemical inertness, excellent dielectric stability and a low coefficient of friction, non-stick industrial coatings offer a balance of properties unbeatable by any other material. With an industrial Teflon coating, the coefficient of friction is generally lowered to a range of 0.02 to 0.15, depending on the load, sliding speed, and type of coating used. Dry lubricant coatings are special versions of Chemours technology designed to provide lubrication under high-pressure/velocity (PV) conditions.

These products are solvent-based, one-coat systems that are usually cured between 148°C/300°F and 371°C/700°F. Teflon coating services can be applied to carbon steel, aluminium, stainless steel, steel alloys, brass and magnesium as well as non-metallics such as glass, fiberglass, some rubber and plastics. Optimum adhesion is obtained by roughening the surface before applying the industrial coating.