- Home

- Our Services

- Kolsterised Surface Treatment

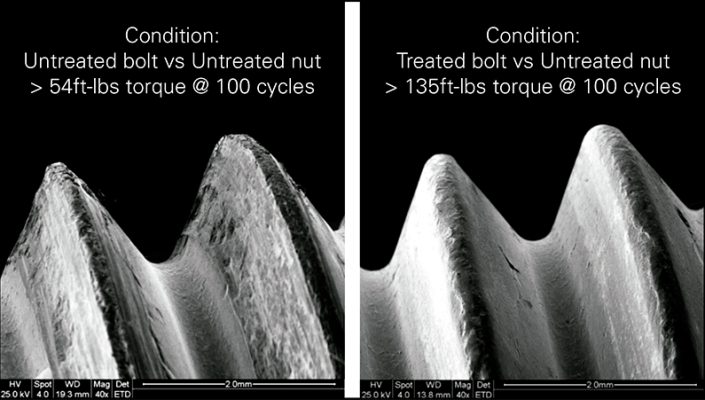

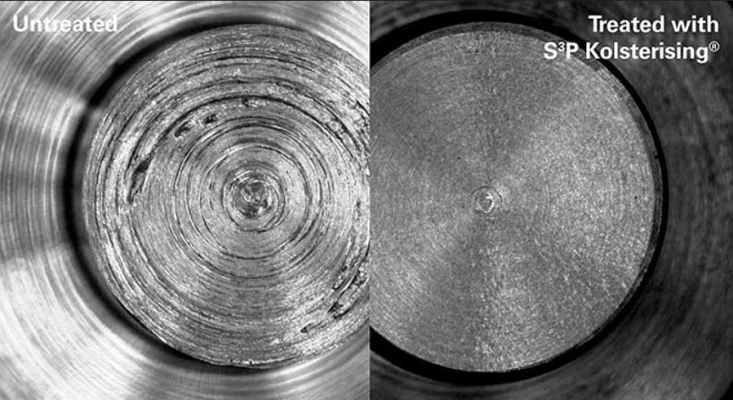

Kolsterising is not a coating but a low-temperature surface carbon diffusion treatment that enhances the hardness of an alloy 4-5 times that of the base material. The process adds large concentrations of carbon atoms that form high compressive stresses on the surface.

Kolsterising is a low temperature, thermo-chemical, diffusion-based surface hardening technology that is used to enhance the inherently poor mechanical and tribological properties of austenitic stainless steels, according to Derek Dandy, a medical market development engineer at Bodycote.

It can be used on stainless steels, cobalt and nickel-based alloys, offering hardness and improved mechanical and wear properties without corrosion resistance loss.

Kolsterising is a low temperature, thermo-chemical, diffusion-based surface hardening technology that is used to enhance the inherently poor mechanical and tribological properties of austenitic stainless steels, according to Derek Dandy, a medical market development engineer at Bodycote.

It can be used on stainless steels, cobalt and nickel-based alloys, offering hardness and improved mechanical and wear properties without corrosion resistance loss.